J4 Tipper Body Certification

With the NHVR's VSB6 modification code J4 now in force, which pertains to tipper body design, BTT Engineering is proud to announce our groundbreaking J4 tipper body certification system. This package aims to redefine industry expectations, providing an adaptable and cost-effective solution for transport operators across Australia. We have already rolled out this service to numerous clients and had fantastic feedback to date.

What is J4 Certification for Tipper Bodies?

The National Heavy Vehicle Regulator (NHVR) released their latest revision to Vehicle Standards Bulletin (VSB) 6 in June 2023, which included a new J4 certification code relating to the design of tipper bodies. This code took the basic requirements in code J1 and expanded on them, adding new requirements for safety systems and structural performance of tipper bodies. The J4 certification code is a design code which works in conjunction with the existing J1 code. How this works is that a J1 signatory can certify the fitment of a tipper body provided that the design of the tipper body has already been certified under the J4 modification code. Being a technical code, this has widely been adopted by the various jurisdictions as limited to qualified engineering personnel due to the nature of the calculations and assessments required

Our J4 Tipper Body Design Package - Developed for Industry

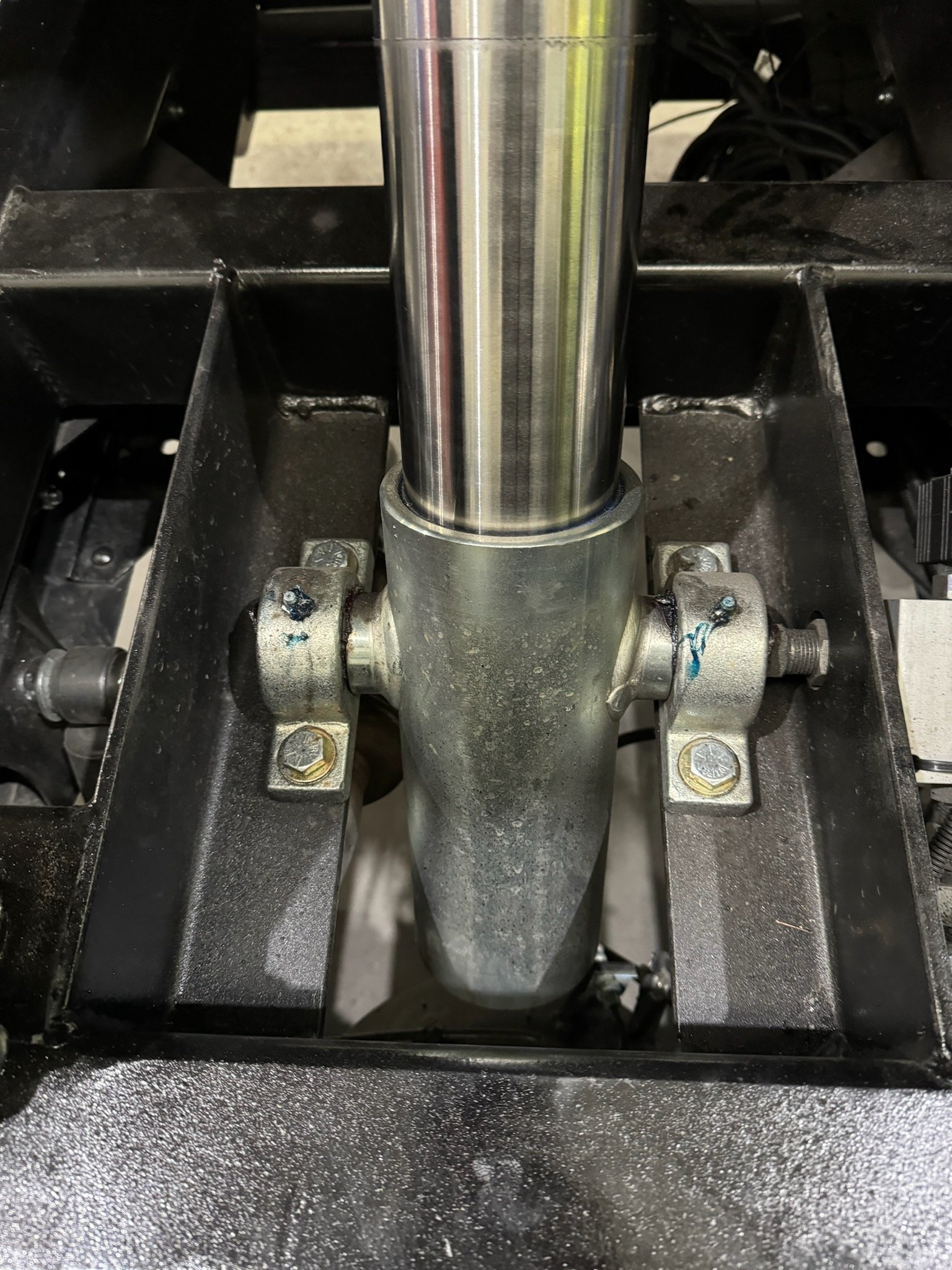

Following extensive consultations with clients in the transport sector, it became clear that the scope of a J4 design certification could be overly restrictive, particularly given the wide variety of configurations required by operators. In response to this, BTT Engineering has developed an innovative certification system that deconstructs the critical design components of a J4 certification down to a subassembly level. This approach provides greater flexibility for clients when constructing their tipper bodies. By treating each subassembly as an independent unit, operators can mix and match components to suit their specific needs—whether opting for a front-mount or centre-mount hoist—while also benefiting from cost savings on common subassemblies, such as tipping pivots and subframes, which can be consistent across all body builds. Each design contains ranges for minimum and maximum dimensions on important components, allowing for flexibility without requiring re-assessment.

Why does this benefit transport operators?

This modular approach allows clients to begin with a single J4 design certification and, if necessary, request additional subassemblies in the future without affecting the integrity of the original design. The flexibility to scale and adapt the design as operational requirements evolve is a key benefit of this system.

Our background with the NHVR VSB6 J4 tipper body design modification code

The process of determining the optimal method for assessing various subassemblies within the J4 design framework has been a significant undertaking for BTT Engineering. Our journey began in 2023, when the J4 code was first introduced. Over the course of its development, we worked closely with the NHVR, engaging in numerous discussions and feedback sessions to ensure the final code aligned with industry expectations. As part of our research, we examined the loading effects on tipper bodies, drawing on both VSB6 J4 design code guidelines and various Australian Standards. Additionally, a formal study by simulation expert Jakob Haas was completed, whose award-winning analysis of load transfer dynamics has proven invaluable in shaping our approach.

Armed with this extensive knowledge and expertise, BTT Engineering is well-equipped to deliver certified J4 tipper body designs that meet the highest standards of safety and performance.

J4 Tipper Body Design Certification Packages | Flexible & Cost-Effective Solutions

While our subassembly-based approach offers significant advantages to manufacturers with existing designs, we also recognise the needs of those without fixed configurations. For manufacturers seeking a ready-to-use J4 design, BTT Engineering offers pre-packaged tipper body design templates. These packages include detailed drawings and components that can be quickly customised to suit specific requirements, such as selecting a front-mounted or underbody hoist. This streamlined process significantly reduces the time and cost involved in modelling, assessing, and detailing individual components, offering a fast and efficient pathway to J4 certification. Clients can even opt for a hybrid system and have some components matching our pre-designed items and others being designed and assessed specifically for their use only - saving time and money where appropriate while not having to compromise on their design goals.

Our certification process

Initial consultation

All J4 tipper body certification jobs should start with contact with an AVE prior to starting works. This prevents any issues later on with already constructed assemblies requiring reinforcement or even worse, replacement. BTT will usually hold a 1-2 hour meeting with any client looking to get a J4 certification to find out more about the tipper bodies they build, key considerations and design limitations. Our aim is to certify as much of your fleet as possible under a single J4 design, with the option to include alternate subassemblies where variations exist. If certain components are repeated across models, future J4 assessments will cost less. Pricing for individual subassemblies is available upon request.

assessment phase

To start the assessment phase, we will either be provided with existing 2D or 3D drawings for the tipper body design or for an additional fee we can come out to site and measure up any example build you may be able to get access to. Each component will then be assessed via finite element analysis to determine if it is suitable for the required loadings, which may include additional safety factors required by the standard. We will keep our clients updated throughout the process and advise of any subassemblies that might need their design updated, along with any suggestions on the best possible way to do this from our experience. Once the assessment phase is complete, manufacturer’s can start building. If on a tight timeline, we will stagger the build process to match your order of construction, preventing any additional delays!

Delivery phase

BTT Engineering will compile all the results from the assessments, along with third party documentation where appropriate, into a complete J4 package. The final documentation will include structural reports, details of the hydraulic systems and verification documents, such as an easy to follow checklist for any J1 signatory to come and finish the certification part of things.

Frequently Asked Questions

-

No! One J4 design can be used as many times as you like. BTT’s J4 design certification aims to allow a wide scope of what can be built

-

Once all details are provided to BTT Engineering, a J4 design is expected to take 3-4 weeks from start to finish - assuming there are no variations

-

Not necessarily! We’ve worked with a number of manufacturers and some were found to already comply with the J4 requirements as they were, barring a couple of new valves and alarms

-

This will depend on the amount for work required, whether a site visit is needed to get dimensions, and whether any design changes are required

-

Once your J4 certification has been completed, you must retain all documentation to present to a J1 signatory when validating the design. In some states, such as Victoria, the J4 will have also been lodged within the AVE scheme