Turning Compliance Challenges into Competitive Strength for Complete Truck Bodies

In close collaboration with local tipper manufacturer Complete Truck Bodies, BTT Engineering has delivered comprehensive compliance documentation for their tipper body design—enabling the majority of their fleet to be certified under a single J4 design. This work was completed in full alignment with the National Heavy Vehicle Regulator’s (NHVR) Vehicle Standards Bulletin 6 (VSB6), Section J4, which sets out the compliance requirements for tipper body design.

More Client Success Stories

Strategic Certification Process for Real-World Outcomes

The newly released J4 design code introduces more rigorous requirements for tipper body design, presenting a challenge for Australian manufacturers to remain competitive against imported equipment. In response, BTT Engineering focuses on turning this compliance burden into a strategic advantage—enabling clients to continue building with their preferred materials and layouts, enhance tipper safety through the integration of advanced electronic and hydraulic systems, validate structural integrity, and showcase the quality of locally manufactured designs, through a cost-effective and time efficient process that ensures full fleet compliance.

To help Complete Truck Bodies stay productive during certification, BTT Engineering staggered the delivery of assessments in line with the release of the client’s drawings. This meant they could continue building their design while receiving staged certification approvals — a process that ensured compliance and continuity of production at the same time.

Scope of Work

Our team worked alongside DRT to remove roadblocks and lay the groundwork for long-term fleet performance.

Structural Assessments of critical components such as the body prop, ram cross-member, bin connection, tailgate mechanisms, bin pivot assembly, subframe, and mounting plates — all assessed to withstand the vehicle’s maximum load-carrying capacity.

Hydraulic/Pneumatic P&ID Schematics covering all hoist variants under the single J4 code, supported by supplier documentation where appropriate.

Operational Safety Measures, including documentation for alarms, fail-safe controls, and lockout systems to ensure safe tipping operations and emergency response capability.

Our streamlined process meant the client was able to certify the majority of their tipper fitments under one robust and flexible J4 design, reducing both administrative overhead and long-term compliance costs.

Efficient, Tailored, and Thorough

Spearheaded by BTT Engineering Mechanical Engineer Jakob, the project was completed within four weeks of receiving the client’s drawings. The process was designed with flexibility in mind, allowing the incorporation of alternate structural components and effectively future proofing the client’s J4 documentation. By accommodating interchangeable items within the certified design, BTT Engineering also helped minimise the cost of future certifications for similar configurations.

Client-Driven Outcomes

It was a pleasure working with Complete Truck Bodies on this project. As an experienced and reputable tipper body builder, their team recognised the value that the J4 design code brings to the industry in terms of improved safety and compliance and were enthusiastic about delivering this added quality to their clients.

Following our analysis, we found that their designs were already exceeding many of the new J4 requirements—meaning only minimal adjustments were needed to achieve full compliance.

We’re grateful for the strong partnership that developed with Complete Truck Bodies throughout this process. Here’s what they had to say:

“Upon signing up with BTT Engineering for the J4 requirements, we have been working in closely with Jakob.

Jakob and the extended team have guided us through the process of the J4 with advice and ease for the project.

Throughout the project we have been able to continue the build as BTT Engineering have staggered the different stages to suit us, thus achieving our requirements.

We have had an excellent relationship with Jakob who has extended the courtesy of answering any questions and advised us on the project as we required the information, he has been easily contactable and the project was obtained in the time frame we originally proposed.

A huge thankyou to Jakob and the team at BTT Engineering for their time, expertise and keeping the project moving to achieve our goal. We will be using them in the future for other projects.”

Complete Truck Bodies’ tailgate design

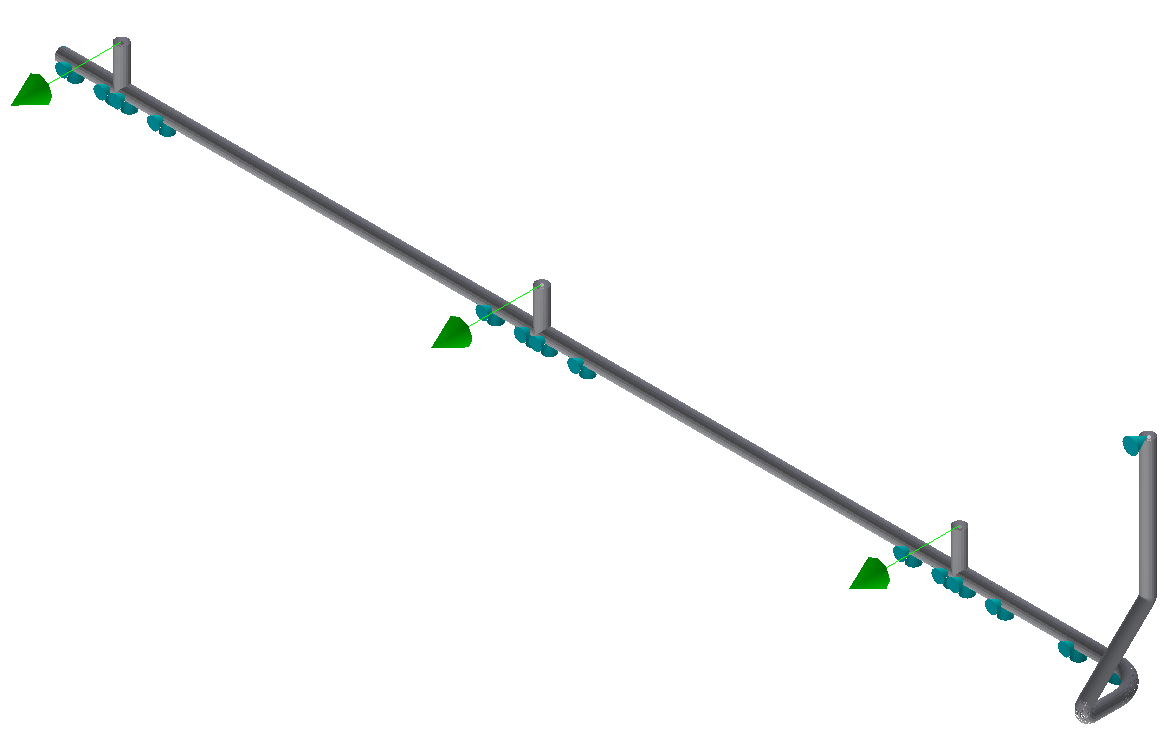

Analysis setup of Complete Truck Bodies’ tailgate locking design

Related Editorial Posts

Analysis results of Complete Truck Bodies’ tailgate structure

Why choose BTT Engineering for your J4 Certification Requirements?

At BTT Engineering our team works directly with manufacturers to ensure designs not only comply, but remain buildable, cost-efficient, and safe for real-world operations. By maximising the coverage of a single J4 certification, we help our clients project their investment across their entire fleet. If you're looking for guidance through the J4 compliance process, please contact us and one of our team will be in contact shortly.